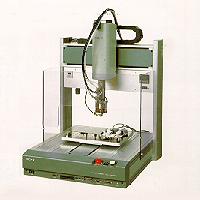

We recommend Cast, because: Sony's desk-top robot, "Cast" has its own history and reputation of the personal FA robot. With its easy-operation and flexibility, Cast has offered various types of performance all over the world. We released new applications now. Consider Cast if you expect more.

Specifications

- Tool specification for Cast-SA1:

- Hot-air unit (name): NC heater (Toyo technical)

- Hot-air unit (model): NCH-IML (Sony specification)

- Hot-air unit (out-put): 100V 450W

- Temperature of hot-air unit: 400~500 Celsius

- Parts handling: vacuuming

- Applicable parts: electrical parts (QFP, etc)

- Size of applicable parts: 0.65 pitch QFP 10-20

- Maximum size of PC-board: Max. 350 x 250mm

- Parts positioning method: positioning jig

- Work envelop:

- X axis / Y axis: 350mm

- Z axis: 100mm

- R axis: 360 degree

- Maximum speed:

- X axis / Y axis: 500mm/s to achieve the function, there is some limitation. Please refer to the specifications document for the details

- Z axis: 200mm/s to achieve the function, there is some limitation. Please refer to the specifications document for the details

- R axis: 720 degree /s to achieve the function, there is some limitation. Please refer to the specifications document for the details

- Positioning accuracy:

- X axis / Y axis: less than 0.02mm

- Z axis: less than 0.02mm

- R axis: less than +/- 0.1 degree

- Maximum payload:

- Work: 10kg

- Resolution:

- X axis / Y axis: 0.02mm

- Z axis: 0.02mm

- R axis: 0.1 degree

- Machine weight: 60kg

- Operating environmental temperature: 0-~40 Celsius

- Air pressure: 0.5Mpa

- Air consumption: 120N l/min

- Drive method: pulse motor (open loop control)

- Movement method: PTP, CP

- Number of axis controlled: 4-axes simultaneous

- Teaching method: direct teaching through teaching pendant (option)

- Program capacity: 10 types of operation program

- Data storage capacity: 2500 points

- Programming method: memory card (standard accessory)

- Power supply: AC100V +/- 10%, 50/60Hz

- Electrical consumption: 1.5KVA

Features

- Ready-to-use in the existing production line from day 1

- CAST can provide many type of application

- Will be released soon

- High performance: less-expensive & user-friendly. Can save labor in manual assembly line. Improves productivity and product quality.

- Compact: human-size compact body. Professional function achieved by human-size robot body. Can save space in the production line.

- Easy operation: no software programming required. Built-in operation program in robot body or memory card. Easy operation without any professional programming

- Flexible: capable of 4,000 points maximum. Max. 250 points for each operation program. 2 types of program (front/back loading and unloading) available

- Multi-application: new types of application released. Less-expensive screw-fastening robot. Newly developed PC board depaneling robot

- Newly developed hot-air soldering

- No spare parts required, which saves the running cost

- Can achieve high-quality soldering on QFP

- Safety note: be absolutely sure to familiarize yourself with the operating instructions to ensure that this product will be used safety

- The specifications and exterior described in this catalog are subject to change without notice due to improvements

Main Products

automatic screw feeder, assembling robot