By Natasha Lin 2007/09/07

Over 20 years of experience, Yang Chen has developed sharp market senses and expertise to supervise Steel Tube & Pie Making Machines Turn Key Project for both domestic and international markets.

More than two decades experience in professional manufacturer in a wide range of steel tube and pie making machines. Yang Chen Steel Machinery Corp. has clung to its principle of building it corporate foundation upon talent, and been trying to catch up to international standards. Today it is one of the largest turn key supervisors for steel tube/pie making machine, as well as promotes all products under its well know brand YC to Europe. Additionally, the company reached approximately

60% of the market share in Vietnam, Romania and Bulgaria.

More than two decades experience in professional manufacturer in a wide range of steel tube and pie making machines. Yang Chen Steel Machinery Corp. has clung to its principle of building it corporate foundation upon talent, and been trying to catch up to international standards. Today it is one of the largest turn key supervisors for steel tube/pie making machine, as well as promotes all products under its well know brand YC to Europe. Additionally, the company reached approximately

60% of the market share in Vietnam, Romania and Bulgaria.

In an effort to meet the growing market demands, Yang Chen has been striving to maximize its production capacity, enhance the quality and reliability of its products, and stay technologically innovative. According to Sales Manager Jerry Chang, the industry is now facing two major challenges: "On the one hand, fierce competition within the sector has created a tough market environment. On the other hand, manufacturers are under huge pressure from rising material cos."

To overcome these challenges while retaining a competitive edge, Yang Chen counts on a number of strategies that it has developed over the years. While others might focus on the price tag; the secret to Yang Chen's success lies in its business know-how. On the other hand, the company's high quality production confounds copycats! "We carry our own specialized products that set us apart from our competitors" Mr Chang continued. "We pay attention to what the market needs and we build long relationships with our customers. Meanwhile, the major mission of our R&D team is seeking for innovative technology. And we believed quality is above everything, so that we insisted on 'Taiwan-made machine'. We are also has ability for any level of turn-key projects."

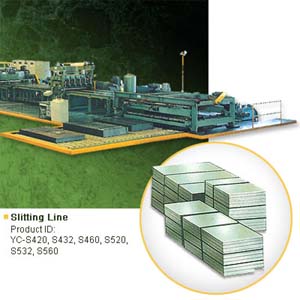

To satisfy customers' needs Yang Chen never stop improving new functions or innovating new skills. This year the company announced new product – Cage Mill obtained the only representation with German and American Technology Alignment. It is capable of grinding the steel tube/pie for a maximums size of 16 inches and caliber of 400 mm. In additionally, Yang Chen offers four standard models of Slitting Lines which can slit various kinds of metals which including cold or hot rolled carbon steel, stainless steel, aluminum, brass, copper, galvanized and special alloys. YC's Slitting Lines can cut coils from 0.2mm up to 6mm; the different size of coils can also be made by customers' orders.

Besides, Yang Chen's other major products include Stainless Steel Tube Making Mill which can make tube from 0.3mm to 8mm with it outside diameter (OD) from 6.5mm to 318mm; End Facing Machines, which can face round tube sizes from 9.5mm to 127mm; Tube Polishing Machine, which can polish square or rectangular tube size from 15mm x 15mm to 120mm x 120mm. To suit for a wide range of market demands, Yang Chen offers all these series with several standard models and also available for customers' made.

Professional design matching requirements to your needs!

With the rapid development of new technologies, Yang Chen is always your best supervisor for turn key project.

With the rapid development of new technologies, Yang Chen is always your best supervisor for turn key project.

" Benefit from over 20 years of technical expertise. We assure our customers' detailed specifications will be met as we assign individual production line for each order." Mr Chang said proudly.

Contact Yang Chen for more information: