| Grade | Br residual induction Gs | bHc coercive force Oe | iHc intrinsic coercive force Oe | Bhmax. maximum energy product MGOe | Working temperature (max.) Celsius | Density g/cm^3 | Curie temperature Celsius |

|---|---|---|---|---|---|---|---|

| Y10t | >/=2000 | 1600-2000 | 1700-2100 | 0.8-1.2 | 250 | 4.8 | 450 |

| Y15 | 2800-3600 | 1600-2400 | 1700-2500 | 1.8-2.2 | 250 | 4.8 | 450 |

| Y20 | 3200-3800 | 1600-2400 | 1700-2600 | 2.3-2.7 | 250 | 4.8 | 450 |

| Y25 | 3500-3900 | 1900-2600 | 2000-2700 | 2.8-3.2 | 250 | 4.8 | 450 |

| Y30 | 3800-4200 | 2000-2700 | 2100-2800 | 3.3-3.7 | 250 | 4.8 | 450 |

| Y15h | >/=3100 | 2900-3100 | 3000-3200 | >/=2.2 | 250 | 4.8 | 450 |

| Y20h | >/=3400 | 3100-3300 | 3200-3400 | >/=2.7 | 250 | 4.8 | 450 |

| Y25bh | 3600-3900 | 2200-2700 | 2400-2900 | 3.0-3.4 | 250 | 4.8 | 450 |

| Y30bh | 3800-4000 | 2800-3000 | 2900-3050 | 3.4-3.8 | 250 | 4.8 | 450 |

| Y34 | 3650-3750 | 3200-3300 | 3800-4000 | 3.3-3.5 | 250 | 4.8 | 450 |

| Y35 | 4000-4400 | 2200-2800 | 2300-3000 | 3.8-4.2 | 250 | 4.8 | 450 |

Features

- Wide variety of grade formulations to meet the most demanding application

- Excellent value when examining cost versus performance

- Capable of long term exposure to high temperatures without negative effects

- Not subject to oxidation when used in harsh environments

- Plentiful non-strategic raw materials insure uninterrupted product availability

- Can be magnetized and calibrated after assembly

- Not subject to self demagnetization when properly utilized

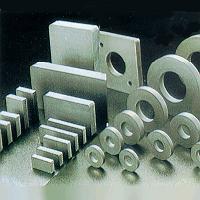

- Available in a variety of geometry's including small and large blocks, arc segments, and rings

- Suitable for use in automotive, industrial, consumer and medical applications

- High coercive forces insure product stability over wide range of operating conditions

- Low field strengths required for saturation makes magnetizing after assembly practical

Main Products

magnet